Advanced EGR Valve Control Module for Enginetech Systems

Detailed Case Study

Softwise Mechatronics: Developing an Advanced EGR Valve Control Module for Enginetech Systems

Introduction

Enginetech Systems, an IATF 16949 certified manufacturer of automotive systems, has been a key supplier of Exhaust Gas Recirculation (EGR) valves to several automotive manufacturers. As the automotive industry evolved, so did the requirements for EGR systems. Enginetech Systems faced a significant challenge when one of their OEM customers developed a new vehicle model with a revised engine control architecture.

In the previous system, the EGR valve motor was directly controlled by the engine's Electronic Control Unit (ECU). However, the new model delegated the motor control functionality to a separate controller. This architectural shift meant that Enginetech Systems needed to develop a standalone EGR valve controller that could receive commands from the ECU over a CAN bus and independently manage valve positioning.

Recognizing the complexity of this task and the stringent automotive industry standards, Enginetech Systems partnered with Softwise Mechatronics to develop this crucial component.

Identifying the Problems

Our team at Softwise Mechatronics conducted thorough discussions with Enginetech Systems' team and the technical team responsible for the ECU. We identified several key challenges and requirements:

- Automotive Standards Compliance: The new EGR valve control module had to meet all relevant automotive standards and specifications, including those for electromagnetic compatibility (EMC), temperature tolerance, and vibration resistance.

- Size Constraints: The overall system needed to fit within specified enclosure limits and utilize a single harness, maintaining compatibility with the existing vehicle design.

- Cost Effectiveness: The system cost had to remain within the allocated budget to maintain the product's competitiveness in the market.

- Performance Parity: The new controller needed to match or exceed the performance of the previous ECU-controlled system.

- Communication Protocol: The controller had to effectively communicate with the ECU via CAN bus and accurately interpret and execute positioning commands.

- Precise Motor Control: Accurate control of the stepper motor was crucial for maintaining correct valve positioning under various operating conditions.

- Rapid Development Timeline: The new controller needed to be developed, tested, and ready for production within a tight timeframe to meet the OEM's launch schedule.

Our Solution

Based on our analysis of the requirements and challenges, we developed a comprehensive solution:

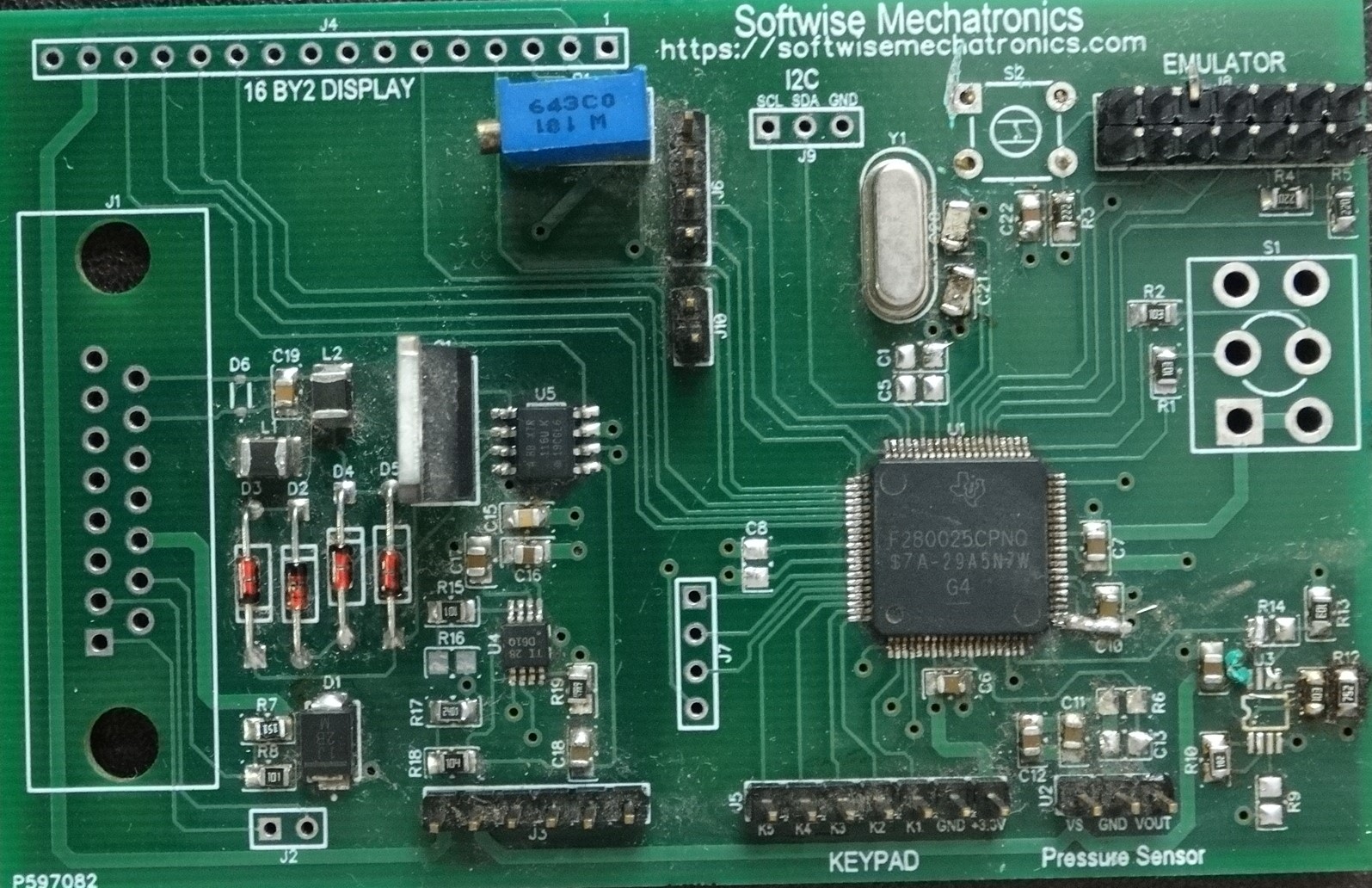

- Hardware Selection: We chose a Texas Instruments automotive-grade microcontroller (MCU) capable of both processing CAN communications and controlling the EGR valve's stepper motor. This selection was carefully vetted and approved by the automotive OEM.

- Circuit Design and PCB Layout: Our engineering team designed a compact circuit and PCB layout that fit within the specified enclosure while meeting all automotive-grade requirements for durability and reliability.

- Embedded Software Development: We developed robust embedded software for the microcontroller, focusing on:

- Efficient CAN communication protocol implementation

- Precise stepper motor control algorithms

- Fail-safe operations and error handling

- Diagnostic capabilities for easier maintenance

- Testing and Integration:

- We created a standalone testing setup that mimicked ECU commands, allowing for thorough testing without needing to remove an ECU from the OEM location.

- A custom rig was developed to measure and record valve angles accurately.

- Once standalone testing was successful, we transferred the setup to the client's location for integration testing with the OEM hardware.

- Validation and Certification: We assisted Enginetech Systems in preparing the necessary documentation and test results for IATF 16949 compliance and OEM certification.

The Result

The EGR valve control module developed by Softwise Mechatronics for Enginetech Systems was a resounding success:

- Performance: The new controller matched the performance of the previous ECU-controlled system, ensuring seamless integration into the new vehicle architecture.

- Compliance: The module met all automotive standards and specifications, passing rigorous EMC, environmental, and durability tests.

- Size and Integration: The compact design fit within the specified enclosure limits and utilized a single harness, meeting the OEM's integration requirements.

- Cost-Effectiveness: The final product remained within the allocated budget, helping Enginetech Systems maintain their competitive edge.

- Timely Delivery: The project was completed within the tight timeline, allowing Enginetech Systems to meet their OEM customer's production schedule.

- Enhanced Capabilities: The standalone controller provided improved diagnostics and the potential for future feature enhancements through software updates.

This successful project not only solved Enginetech Systems' immediate challenge but also positioned them as a capable supplier ready to adapt to evolving automotive architectures. It demonstrated Softwise Mechatronics' expertise in automotive-grade embedded systems development, particularly in the critical area of emissions control technology.

The new EGR valve control module has since been successfully integrated into the OEM's production vehicles, with plans to adapt the design for other vehicle models and manufacturers in the future.

Other Case Studies

Innovative Thread Grinding Software Solution for CNC Machine Manufacturer Read Developing Indigenous CNC Controllers for EDM Machines Read Advanced Communication Controller for Defense Project ReadIndustries We Serve

Automotive Learn More Consumer Electronics Learn More Defense and Aerospace Learn More Energy and Utilities Learn More Industrial Products and Machine Tools Learn More Pharma Equipment and Manufacturing Learn MoreReady to Get Started?

Let's discuss how our services can elevate your engineering projects.

Contact Us Today