Embedded Systems Development

Delivering cutting-edge engineering solutions to global industries

End-to-End Embedded Systems Expertise

- Full-spectrum services from concept to production-ready systems

- Expertise in both hardware and software aspects of embedded systems

- Adherence to international standards (ISO/IEC, CE, and others)

- Agile development methodology with regular client touchpoints

Tailored Embedded Solutions for Diverse Industries

- Wireless and Industrial Communication Protocols (BLE, WiFi, LoRa, CAN, EtherCAT, MODBUS)

- Automotive: Embedded systems for vehicle control units and ADAS

- Defense and Aerospace: Mission-critical embedded systems

- Industrial Products: Automation solutions for smart factories

- Industrial Machine Tools: Advanced embedded controllers and HMIs with IoT capabilities

- Healthcare: IoT-enabled medical equipment and FDA-compliant systems

Cutting-Edge Embedded System Capabilities

- Microcontroller and Microprocessor Programming (Texas Instruments, ST Microelectronics, ARM, PIC, AVR, x86)

- FPGA Design and Implementation (Xilinx, Intel/Altera)

- Real-Time Operating Systems (FreeRTOS, VxWorks, QNX)

- IoT Device Development and Integration

- Low-Power Design for Battery-Operated Devices

Related Case Studies

Revolutionizing Legacy Testing Machines

IntroductionUbique BCT HMI.png 504.18 KBA prominent manufacturer of testing equipment was facing significant challenges in maintaining its competitive edge in the international market. Although their machines were built to the highest standards, they severely lacked modern electronics, data acquisition capabilities, and connectivity features. As a result, the company was losing sales, particularly in the pharmaceutical sector, to international competitors whose machines offered advanced features and full compliance with the latest US FDA regulations.The manufacturer turned to Softwise Mechatronics to modernize their entire product line, bringing it on par with the most advanced machines in the industry. We began by identifying the key issues in their current systems, benchmarking against competitors, and understanding the needs of their user base.Identifying the ProblemsWe held extensive meetings with the client's team, from senior directors to assembly line technicians. We also engaged with the marketing department, after-sales support teams, and some of their trusted customers.Challenges Faced by the ClientMany of the existing machines were either purely mechanical or had minimal digital displays.The machines lacked features such as access control, real-time graph displays, and reporting capabilities. They were also unable to connect with Lab Management Systems (LMS) or ERPs.Compliance with US FDA 21 CFR Part 11 regulations was a key requirement, particularly for their pharmaceutical customers exporting to the US. Without this compliance, customers would be forced to switch to other suppliers.The machine portfolio had varied controllers and displays, resulting in increased inventory costs.Technical issues with the machines could only be diagnosed by sending personnel to the customer site, leading to delayed service.Customer Pain PointsWhile the machines were cutting-edge when first introduced, they had become outdated in both design and functionality.The absence of user access control, real-time operation graphs, and flexible reporting options was a major drawback. Most machines were only compatible with dot-matrix printers, limiting reporting options.Customers increasingly wanted their machines to integrate with LMS or ERP systems, which the current models could not support.The machines were typically operated by blue-collar technicians, while quality managers were responsible for test setup and data interpretation. In many cases, managers working remotely or from a different location had to travel to the facility to make even minor adjustments.Our SolutionAfter thoroughly studying the entire product line, we discovered that all the machines operated on the same fundamental principle, with variations in inputs and outputs. Most machines utilized load cells or pressure sensors with strain gauges, along with additional inputs such as encoders, digital I/O, or safety interlocks. Based on this analysis, we developed the following strategy:Unified Controller: We designed a common controller capable of handling all possible inputs and outputs, with extra provisions for future developments.User Interface: The UI was built on a Linux-based SBC (Single Board Computer), providing features such as printer connectivity and integration with ERP or cloud systems. This design allowed us to use different screen sizes depending on the machine type while delivering a modern, user-friendly experience with real-time graphing and reporting capabilities.Access Control: Specific access levels were created for Operators, Managers, System Administrators, and the Client as the OEM.Remote Access for Setup and Review: A provision was made for users to log into the machine remotely within their company’s network to set up tests and review results, while actual machine operation was restricted to the local console.Remote Diagnostics: We enabled remote access for the client’s service team, allowing them to diagnose issues before dispatching personnel to the site, minimizing downtime.The ResultWe successfully developed a machine controller based on the Texas Instruments MSP432 microcontroller, paired with an Analog Devices ADC. The user interface was deployed on a Linux SBC running in kiosk mode using Node.js. The final product boasted a sleek design, best-in-class data sampling rates, real-time graphs, and all the features defined at the start of the project. The system achieved a stable accuracy of more than 0.01% of the machine’s capacity.These upgraded machines have been successfully installed at numerous pharmaceutical manufacturing plants, with many integrated into ERP or Lab Management Systems.Ubique During Development.png 234.34 KBUbique Testing.png 165.46 KB

Read full case study about Revolutionizing Legacy Testing Machines

Advanced EGR Valve Control Module for Enginetech Systems

Softwise Mechatronics: Developing an Advanced EGR Valve Control Module for Enginetech SystemsControl Valve PCB.JPG 484.4 KBIntroductionEnginetech Systems, an IATF 16949 certified manufacturer of automotive systems, has been a key supplier of Exhaust Gas Recirculation (EGR) valves to several automotive manufacturers. As the automotive industry evolved, so did the requirements for EGR systems. Enginetech Systems faced a significant challenge when one of their OEM customers developed a new vehicle model with a revised engine control architecture.In the previous system, the EGR valve motor was directly controlled by the engine's Electronic Control Unit (ECU). However, the new model delegated the motor control functionality to a separate controller. This architectural shift meant that Enginetech Systems needed to develop a standalone EGR valve controller that could receive commands from the ECU over a CAN bus and independently manage valve positioning.Recognizing the complexity of this task and the stringent automotive industry standards, Enginetech Systems partnered with Softwise Mechatronics to develop this crucial component.Identifying the ProblemsOur team at Softwise Mechatronics conducted thorough discussions with Enginetech Systems' team and the technical team responsible for the ECU. We identified several key challenges and requirements:Automotive Standards Compliance: The new EGR valve control module had to meet all relevant automotive standards and specifications, including those for electromagnetic compatibility (EMC), temperature tolerance, and vibration resistance.Size Constraints: The overall system needed to fit within specified enclosure limits and utilize a single harness, maintaining compatibility with the existing vehicle design.Cost Effectiveness: The system cost had to remain within the allocated budget to maintain the product's competitiveness in the market.Performance Parity: The new controller needed to match or exceed the performance of the previous ECU-controlled system.Communication Protocol: The controller had to effectively communicate with the ECU via CAN bus and accurately interpret and execute positioning commands.Precise Motor Control: Accurate control of the stepper motor was crucial for maintaining correct valve positioning under various operating conditions.Rapid Development Timeline: The new controller needed to be developed, tested, and ready for production within a tight timeframe to meet the OEM's launch schedule.Our SolutionBased on our analysis of the requirements and challenges, we developed a comprehensive solution:Hardware Selection: We chose a Texas Instruments automotive-grade microcontroller (MCU) capable of both processing CAN communications and controlling the EGR valve's stepper motor. This selection was carefully vetted and approved by the automotive OEM.Circuit Design and PCB Layout: Our engineering team designed a compact circuit and PCB layout that fit within the specified enclosure while meeting all automotive-grade requirements for durability and reliability.Embedded Software Development: We developed robust embedded software for the microcontroller, focusing on: Efficient CAN communication protocol implementationPrecise stepper motor control algorithmsFail-safe operations and error handlingDiagnostic capabilities for easier maintenanceTesting and Integration: We created a standalone testing setup that mimicked ECU commands, allowing for thorough testing without needing to remove an ECU from the OEM location.A custom rig was developed to measure and record valve angles accurately.Once standalone testing was successful, we transferred the setup to the client's location for integration testing with the OEM hardware.Validation and Certification: We assisted Enginetech Systems in preparing the necessary documentation and test results for IATF 16949 compliance and OEM certification.The ResultThe EGR valve control module developed by Softwise Mechatronics for Enginetech Systems was a resounding success:Performance: The new controller matched the performance of the previous ECU-controlled system, ensuring seamless integration into the new vehicle architecture.Compliance: The module met all automotive standards and specifications, passing rigorous EMC, environmental, and durability tests.Size and Integration: The compact design fit within the specified enclosure limits and utilized a single harness, meeting the OEM's integration requirements.Cost-Effectiveness: The final product remained within the allocated budget, helping Enginetech Systems maintain their competitive edge.Timely Delivery: The project was completed within the tight timeline, allowing Enginetech Systems to meet their OEM customer's production schedule.Enhanced Capabilities: The standalone controller provided improved diagnostics and the potential for future feature enhancements through software updates.This successful project not only solved Enginetech Systems' immediate challenge but also positioned them as a capable supplier ready to adapt to evolving automotive architectures. It demonstrated Softwise Mechatronics' expertise in automotive-grade embedded systems development, particularly in the critical area of emissions control technology.The new EGR valve control module has since been successfully integrated into the OEM's production vehicles, with plans to adapt the design for other vehicle models and manufacturers in the future.

Read full case study about Advanced EGR Valve Control Module for Enginetech Systems

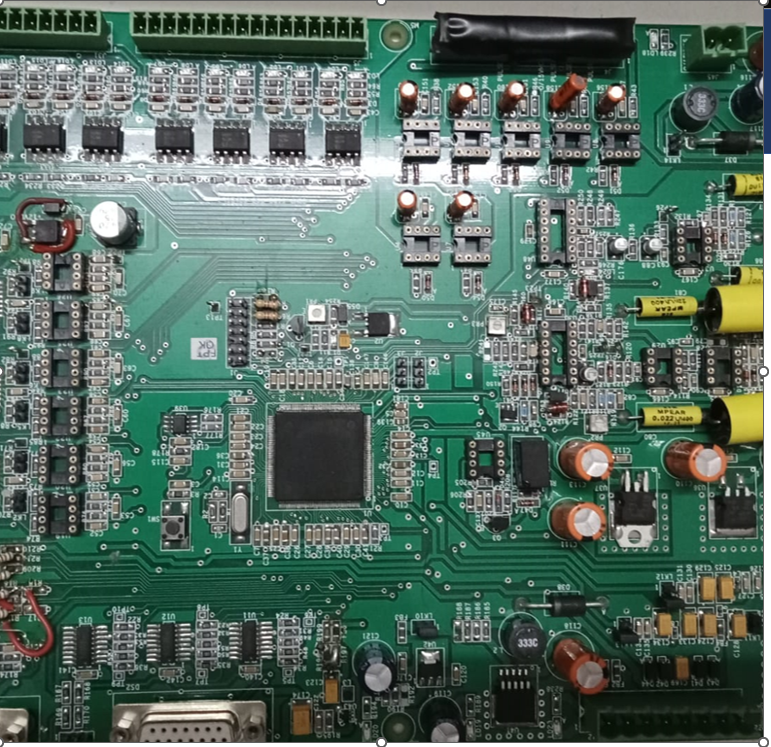

Developing Indigenous CNC Controllers for EDM Machines

Developing Indigenous CNC Controllers for EDM MachinesElectronica EDM PCB.png 1.34 MBIntroductionA prominent manufacturer of CNC Electrostatic Discharge Machines (EDMs) and Wire Cutting Machines was facing a significant challenge. While they had successfully developed most of the components for their machines in-house, including accessory boards and high voltage discharge circuits, they remained dependent on a Taiwanese corporation for the crucial CNC controllers - the heart of their machines.This reliance on imported controllers presented several issues:Limited control over design and featuresInability to differentiate their products from competitors using the same controllersChallenges in implementing customer-requested featuresPotential supply chain vulnerabilitiesTo address these challenges and gain a competitive edge, the manufacturer partnered with Softwise Mechatronics to develop an indigenous CNC controller that could match or exceed the performance of the imported units.Identifying the ProblemsOur team at Softwise Mechatronics conducted extensive meetings with the client's team, including senior engineers and technicians. We focused on understanding:The EDM process and its critical parametersFactors affecting metal removal rate and surface finishLimitations of the client's original prototypeDesired improvements over the imported controllersThrough these discussions, we identified several key issues:Inadequate sampling rates in the original prototypeSuboptimal interrupt priorities affecting performanceLack of customization options in the imported controllersNeed for improved surface finish and material removal ratesDesire for modern user interface and data storage capabilitiesWe categorized our objectives into three priority levels:Must-haves:Superior surface finish compared to standard controllersOptimized control parameters for each machine modelFaster material removal rate than imported controllersGood-to-haves:Ability to store machining data during power failures without external batteriesModern, Linux-based user interface to avoid OS licensing costsStretch goals:Additional advanced features as requested by long-standing customersOur SolutionBased on our analysis, we developed a comprehensive solution:Hardware Selection: We chose a high-end dual core TI C2000 series microcontroller with 32 but floating-point architecture, for its powerful processing capabilities and real-time control features.Circuit Design: Our team completed the circuit design and PCB layout, ensuring seamless integration with the client's existing boards and circuits.User Interface: We selected a robust Linux Single Board Computer (SBC) for the graphical user interface. Leveraging the client's existing C++ source code for their Windows-based GUI, we redesigned the interface for a more modern look and feel while adding new modules for advanced features.Embedded Software: Our development team focused on optimizing the control algorithms to achieve better surface finish and material removal rates. The insights provided by the client's senior engineers were invaluable in fine-tuning these parameters.Integration: We ensured that the new controller could seamlessly control all machine axes while maintaining or improving upon the performance of the imported units.The ResultThe indigenous CNC controller developed by Softwise Mechatronics exceeded expectations:Performance: The new controller achieved both better surface finish and faster material removal rates compared to the imported units.Customization: The client gained full control over the controller's design, allowing them to implement unique features and respond quickly to customer requests.User Experience: The modern, Linux-based interface provided an intuitive and responsive user experience.Data Management: Improved data storage capabilities enhanced the machine's reliability and reduced downtime.Cost-Effectiveness: By eliminating dependency on imported controllers, the client reduced costs and improved their profit margins.Market Differentiation: The custom controller allowed the client to offer unique features, setting their machines apart in a competitive market.The successful development of this indigenous CNC controller not only solved the client's immediate challenges but also positioned them for long-term success in the EDM and Wire Cutting Machine market. The project demonstrated Softwise Mechatronics' expertise in control systems, embedded engineering, and software development, particularly in the specialized field of EDM technology.

Read full case study about Developing Indigenous CNC Controllers for EDM Machines

Advanced Communication Controller for Defense Project

IntroductionA niche defense equipment and subsystems manufacturer faced a complex challenge in one of their critical projects: upgrading a ship's radar system. The project required seamless integration of multiple communication protocols and precise platform stabilization. Recognizing the need for specialized expertise, the company approached Softwise Mechatronics to develop an embedded solution that could bridge these diverse protocols within stringent time constraints.Identifying the ChallengesThrough comprehensive discussions with the client's engineering team and a thorough analysis of the project requirements, we identified several key challenges:Protocol Diversity: The main computer used a proprietary protocol based on RS485 with non-standard baud rates, while other components used different protocols: Motor drives: EtherCAT protocolEncoders: EnDat 2.0 protocolReal-time Communication: The system required real time message conversion between these protocols to ensure optimal radar performance within microsecond level delays.Platform Stabilization: The radar needed to be installed on a stabilized platform, requiring precise control and feedback mechanisms.Environment: The solution needed to be robust enough to withstand the harsh conditions of a naval environment.Time and Budget Constraints: The project had strict deadlines and budget limitations.Our SolutionBased on our analysis and expertise, we developed a comprehensive solution:Hardware Selection: We chose one of the TI's Sitara microprocessor for its powerful processing capabilities, flexibility, and support for multiple communication interfaces.Software Development: Implemented the EtherCAT stack for motor control communication.Integrated EnDat 2.0 protocol libraries for precise encoder readings.Developed custom firmware to handle the proprietary RS485-based protocol.Protocol Conversion: We designed an efficient message routing and conversion system to seamlessly translate between the different protocols in real-time.Platform Stabilization: Implemented a sophisticated feedback control system using the encoder data to maintain platform stability in various sea conditions.Optimization: Fine-tuned the system to meet the strict timing requirements, ensuring all protocol conversions occurred within the specified limits.Technical Deep DiveCommunication ProtocolsRS485 (Proprietary): A robust, differential signaling standard capable of long-distance communication.We implemented a custom driver to handle the non-standard baud rates required by the main computer. EtherCAT: A high-speed Ethernet-based fieldbus system developed by Beckhoff Automation. Offers precise synchronization and deterministic communication, crucial for coordinated motor control. We utilized the EtherCAT stack to manage real-time communication with the platform motors.EnDat 2.0: A digital, bidirectional interface developed by HEIDENHAIN specifically for position encoders. Provides high-resolution position data with built-in diagnostics. We integrated EnDat 2.0 libraries to accurately read encoder positions for platform stabilization.Platform Stabilization Feedback ControlTo ensure precise radar positioning regardless of ship movement, we implemented a sophisticated feedback control system:Sensor Fusion: Combined data from EnDat 2.0 encoders and inertial measurement units (IMUs) to accurately determine platform orientation.PID Control: Connected with the Platform Controller which provided the feedback control using the encoders and the motors.The End ResultSoftwise Mechatronics successfully delivered the embedded solution within the specified time and budget constraints. Key achievements include:Seamless Integration: The developed system efficiently converted messages between the proprietary RS485 protocol, EtherCAT, and EnDat 2.0 within the required time limits.Robustness: Extensive testing confirmed the system's reliability in simulated maritime environments.Client Satisfaction: The defense equipment manufacturer expressed high satisfaction with the solution, noting its performance exceeded their expectations.This project showcases Softwise Mechatronics' expertise in embedded systems development, protocol integration, and advanced control systems. Our ability to navigate complex technical requirements while adhering to strict timelines demonstrates our value as a partner for sophisticated defense and industrial projects.

Read full case study about Advanced Communication Controller for Defense Project

Ready to Get Started?

Let's discuss how our services can elevate your engineering projects.

Contact Us Today